Steel Machining & What It Means To You

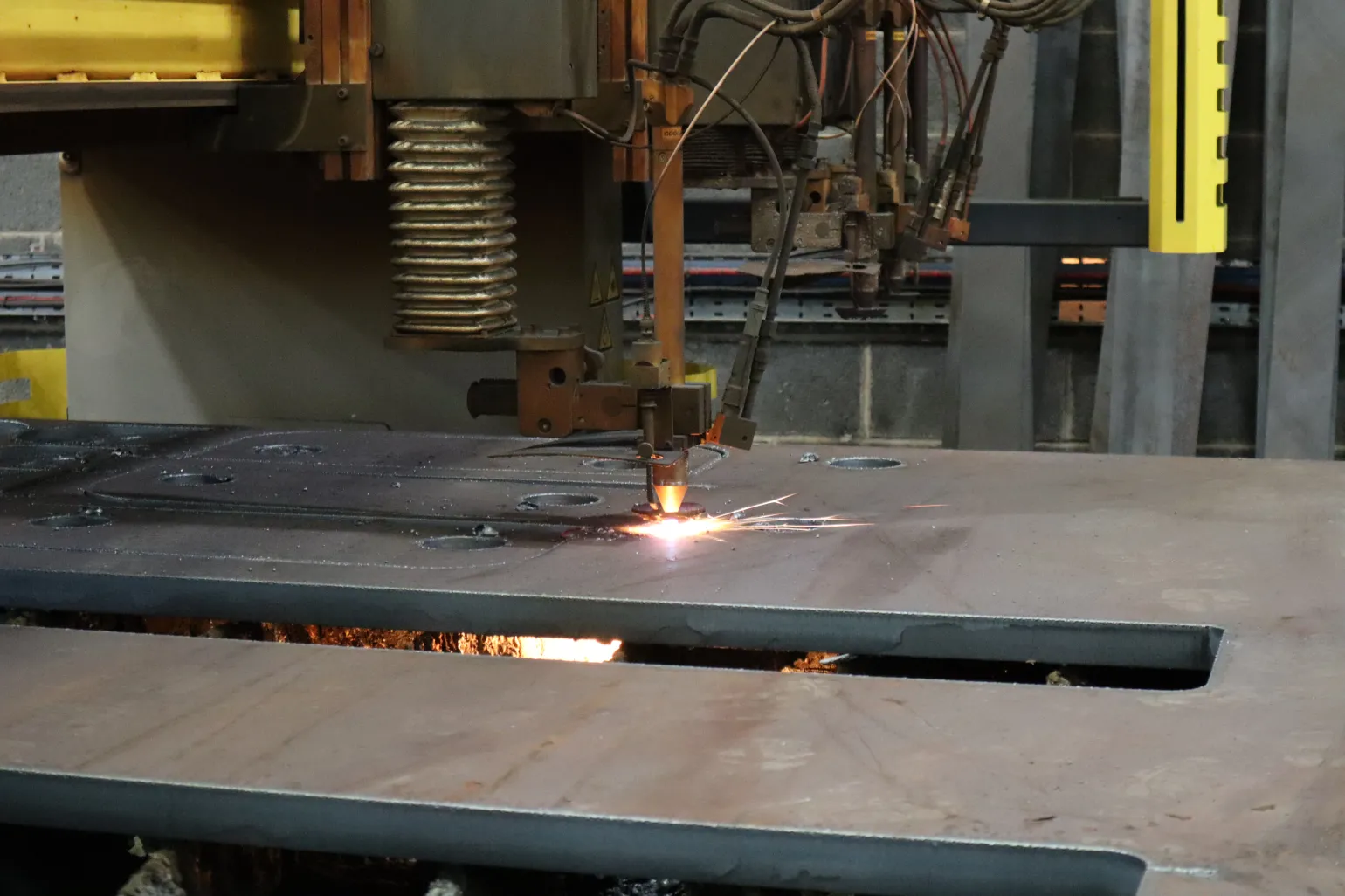

If you need to produce semi-finished or finished parts or products from profiled or cut-to-length high-quality steel, steel machining is the answer. Our machining shop here at Pulman Steel offers steel cutting services as well as profiling and machining services such as chamfering, drilling, and milling. Take a closer look at how our highly skilled mechanists and their computer-guided, specialised machines and tools can help you.

Steel machining is a controlled material-removal process in which steel is cut, drilled, or subjected to other methods to produce a desired final size and shape. All machining methods use machine tools such as steel cutting machines and are known collectively as subtractive manufacturing methods. Entrust your steel milling and other machining projects to Pulman Steel.

Thanks to various specialised steel drill machines, other machines, and tools that are often guided by computers, different steel machining methods are available. The most common of these methods include:

The steel milling process sees a series of cutting edges on a rotary cutter circumference remove chips from the workpiece. During the process, sections of the cutting edges contact the piece of steel while other sections of the edges move freely. The many cutting edges allow for a large volume of steel chips to be removed from the workpiece. We offer reliable steel milling services in the UK.

‘Steel drilling’ is an umbrella term that covers all methods used to create cylindrical holes in steel. The two main steel drilling categories include deep hole and short hole. The difference between the two categories isn’t limited to depth and diameter. There’s also a difference in material removal speed and chip evacuation. Some of the processes included under the term ‘steel drilling’ include counterboring, reaming, and various finishing processes. Most steel drill machines operate using two major movements, namely, a linear feed movement and a rotating key movement.

In steel machining, chamfering refers to a process used to remove the edges of pieces of steel. This is done to prevent the edges from breaking or wearing, to protect parts against friction and people from the risk of injury, and to remove burrs to allow for additional processes or for a better finish. The two types of chamfering include corner chamfers and edge chamfers. The chamfering process sees machinists use special tools to round parts’ edges and contour their silhouettes.

Notching is a steel machining process that is related to shearing. Different notching methods create different products by selectively cutting steel away from the workpiece’s outer edges. End notching, side notching, and tube notching are a few examples of different types of steel notching. The basic process uses a punch press with a steel cutting tool to remove selected sections of unwanted material from the workpiece, which has been secured in place.

In steel machining, tapping is used to shape steel in an extruded or pre-punched hole. This is done to form threads for non-self-tapping screws that will be used to secure two pieces of steel. During the tapping process, rotary tools known as taps are gripped in a chuck, collet, or ‘floating’ toolholder. Different taps are used to produce different threads, such as spiral point taps, spiral flute taps, and forming or roll taps. The taps are driven into the secured steel workpiece at a specific feed rate. Taps might resemble bolts or screws, but on closer inspection, you’ll see that they have sharp edges on the end and on the periphery, as well as grooves running down the sides. The sharp edges cut the threads while the grooves conduct chips up and out of the hole.

Offering steel cutting and steel machining services, Pulman Steel can meet an extensive range of steel processing needs. Whether you’re simply looking for steel milling services you can trust to deliver on time, or you’re looking for a wider range of steel requirements including products, materials, and parts, you will find what you’re looking for with us. Contact our team of experts with your specs, or conveniently place your order online.