Metal saw cutting is a task that requires precision, efficiency, and consistency across a wide range of sections. This is what you can expect when you choose Pulman Steel, where we pride ourselves on delivering high-quality services tailored to meet our customers’ individual needs. Whether you require unique cuts or high-volume production, our reliable and cost-effective saw cutting services are for you.

A metal fabrication process, saw cutting sees steel and other materials cut to specific lengths or shapes with advanced saws for cutting metal. This method is valued highly in the steel industry for its ability to produce clean, precise cuts with minimal waste. Ideal for various applications, metal saw cutting is commonly used in the construction, manufacturing, automotive, and engineering industries.

There are numerous advantages to choosing metal saw cutting to create profiles. Our advanced saws for steel cutting offer benefits such as:

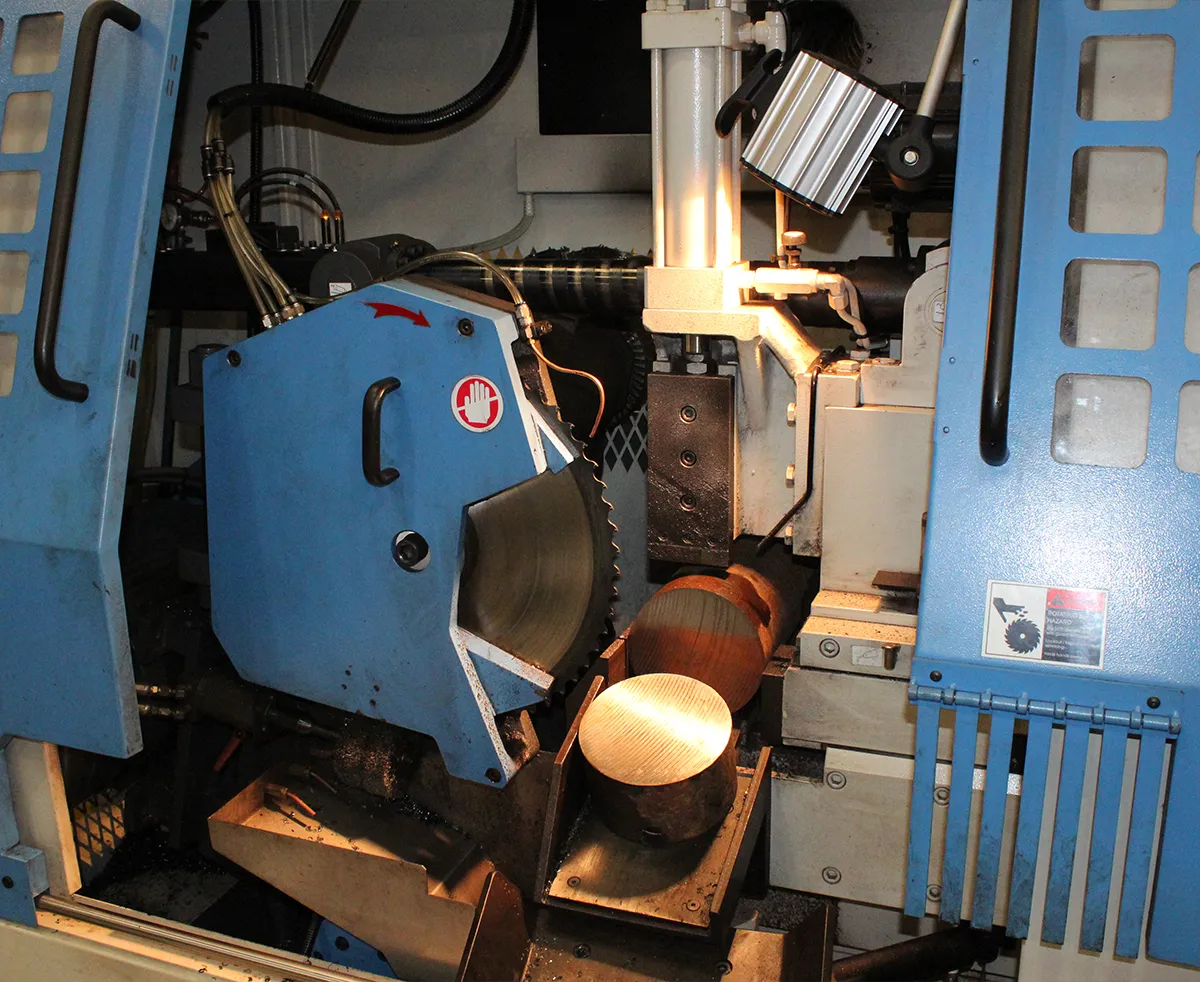

Our saws for cutting metal are designed to handle different materials, thicknesses, and tasks, with the results always characterised by quality and precision:

There are several reasons why our saws for cutting metal are ideal for the job:

Each of our machines has different key features that make them the best choice for various saw cutting jobs. Their key features include:

At Pulmans, we combine advanced machinery with decades of expertise to deliver exceptional saw cutting services. Along with this, our commitment to quality and customer satisfaction sets us apart from our competitors. Some of the best reasons to choose us for metal saw cutting include:

Whether you need precise cuts for large steel sections or intricate smaller components, Pulman Steel has the tools and expertise to deliver outstanding results. Contact us today for a quote or to find out more about how our saw cutting services can help you.