Get precision-cut steel sections tailored to your specifications with Pulman Steel’s industry-leading plasma profiling services. With decades of experience and a commitment to excellence, we serve a wide range of industries across the UK, delivering high-quality results on time, every time. Whether you require custom steel components or complex shapes, our plasma profile cutter and experienced team ensure superior accuracy and efficiency. Turn to us for plasma profiling services you can trust.

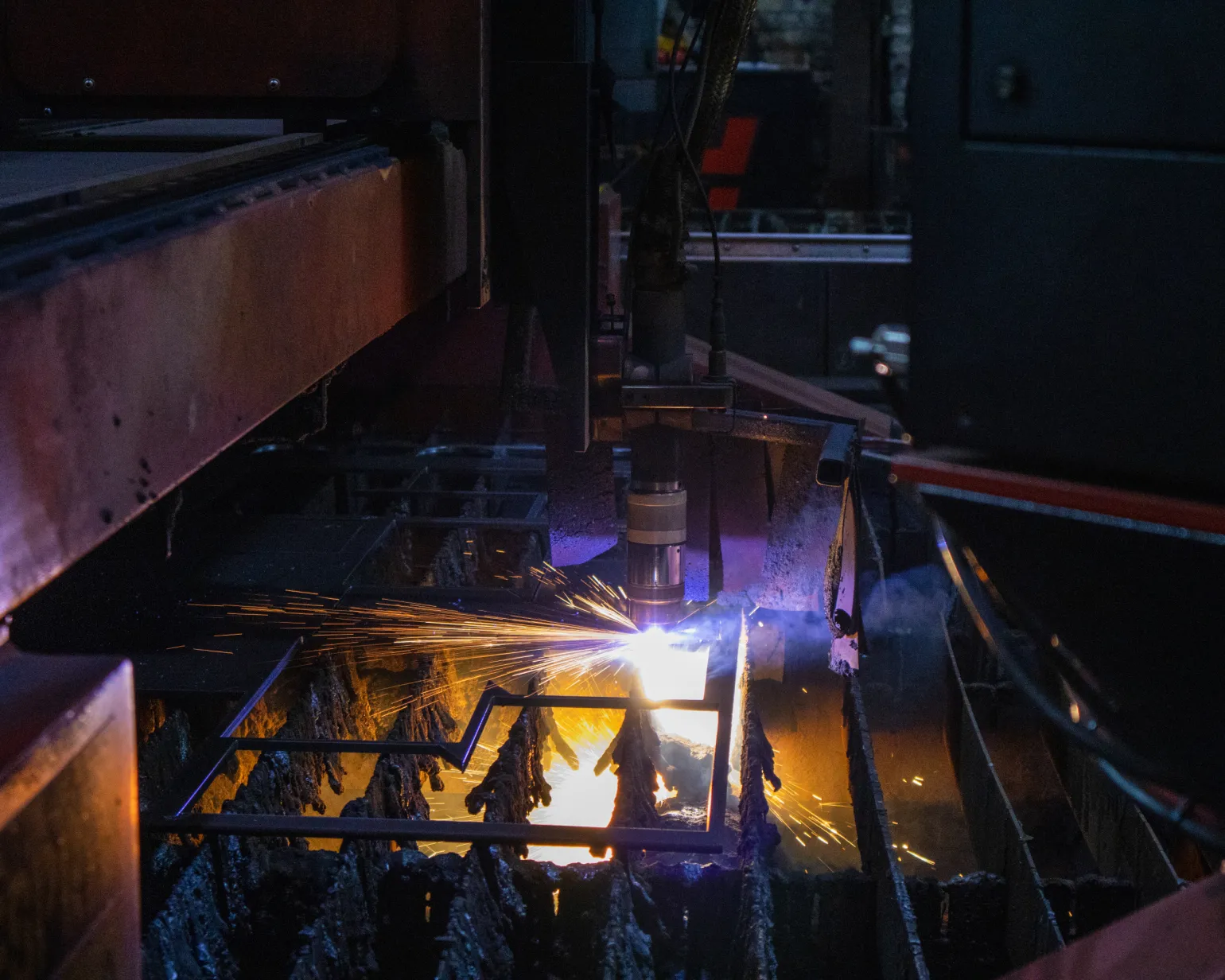

Plasma profiling is a sophisticated metal fabrication process that uses a high-velocity jet of ionised gas (plasma) to cut through electrically conductive materials. This method creates precise, high-quality cuts with minimal distortion, making it ideal for a variety of applications ranging from automotive and construction industries to engineering and manufacturing.

Our plasma profile cutting machine generates an extremely hot and focused arc that melts the metal while simultaneously blowing molten material away. This results in clean, accurate cuts that require minimal post-processing. Whether cutting mild steel or other metals, plasma profiling delivers consistent and reliable performance.

Plasma profiling offers a range of advantages over traditional cutting methods. The main reasons to choose this method at Pulmans include:

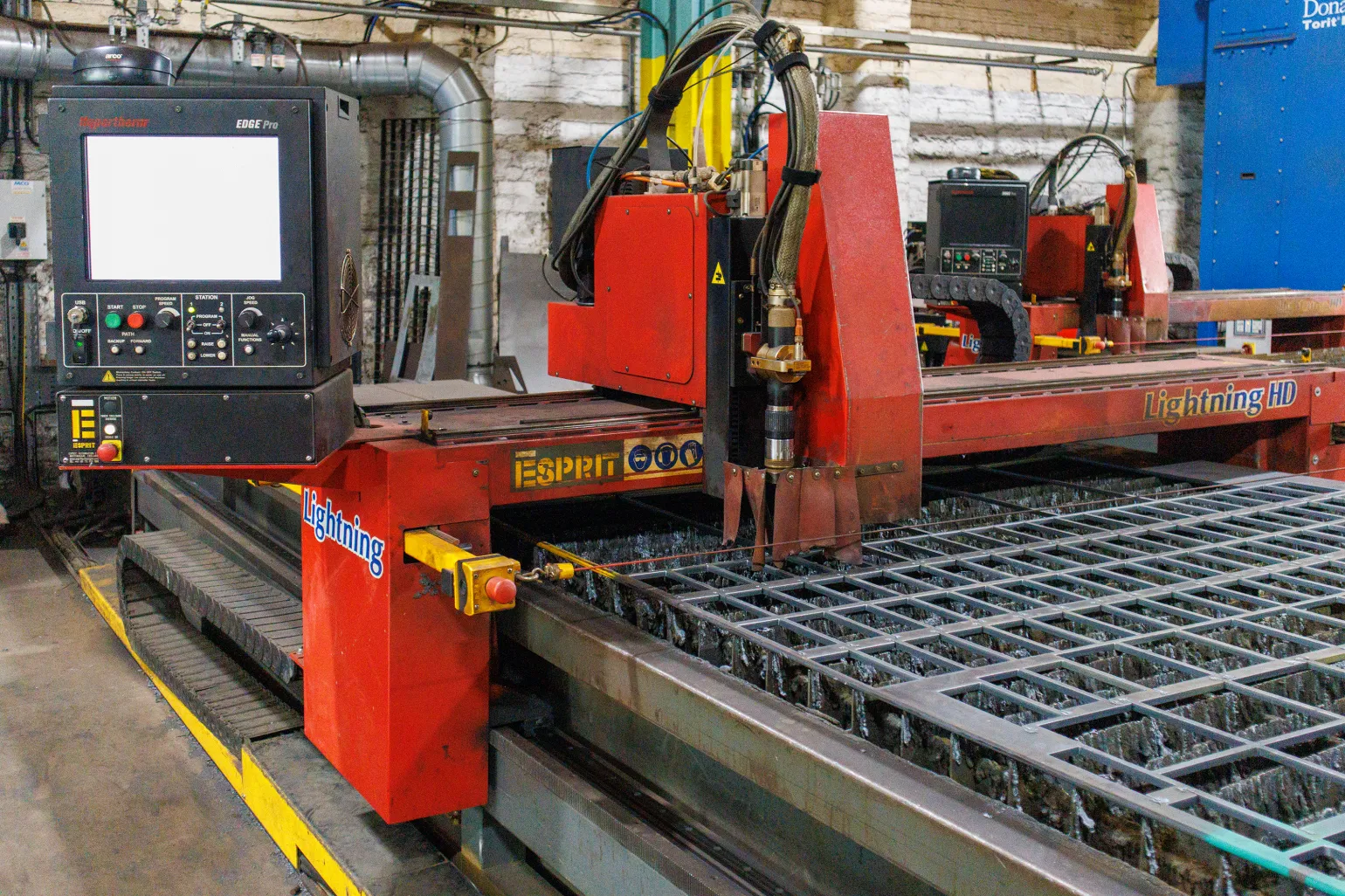

The Espirit Viper and Espirit Lightning plasma profile cutters are at the heart of our plasma profiling operations. These top-performing machines use innovative technology to deliver accurate and consistent cuts quickly across a wide range of steel sections. Their ability to maintain the highest level of quality while handling large volumes makes them an excellent choice for industrial applications.

Our Espirit Viper and Lightning plasma profile cutting machines have several advantages over other machines. Enabling us to meet our clients’ diverse needs, these machines’ advantages include:

High cutting speeds: Fast processing times offer enhanced efficiency and reduced lead

times.

Our Espirit Viper and Lightning plasma profile cutters use advanced technology to ensure top performance. Their key features include:

At Pulmans, we are committed to providing best-quality plasma profiling services that exceed

customer expectations. When you choose us for your plasma profile needs, you benefit from our:

Choose Pulman Steel for your high-precision plasma profiling needs. Contact us today to discuss your requirements, request a quote, or learn more about our plasma profile cutters and services. We’re here to provide tailored solutions that deliver superior results.