Intricate steel shapes, consistent batch production, and one-off custom pieces known for reliability and excellent craftsmanship are more than possible with Pulman Steel’s laser profiling services. Meeting the requirements of diverse industries across the UK, our advanced technology and expertise ensure precision-cut steel sections that fit your exact specifications. Choose us for all your laser profiling needs.

Laser profiling is widely used for cutting steel and other metals, as it allows for complex patterns that would be challenging to achieve accurately with traditional cutting methods. The laser beam used in the cutting process burns, melts, or vaporises the material, leaving an edge that’s clean and precise.

The technique of laser cutting profiles is important for industries that demand high precision, such as aerospace, automotive, construction, and manufacturing. By choosing laser profiles, your business can achieve faster production times, reduce waste, and superior-quality components.

Laser profiling offers numerous advantages over conventional cutting methods, making it a superb choice for a variety of applications. Among its main advantages are:

Versatility: Laser profilers work with a wide range of materials, including aluminium, mild steel, and stainless steel.

High precision: This profiling method can achieve tolerances as tight as +/- 0.1mm, providing unrivalled accuracy.

Complex shapes: Laser profiling allows for detailed designs and complex shapes without the need for additional tooling.

Cost-effective: This method reduces overall production costs by minimising the amount of material wasted and requiring almost no post-processing.

Speed: Our machines for laser-cutting profiles operate at high speeds, offering faster turnaround times for large and small projects.

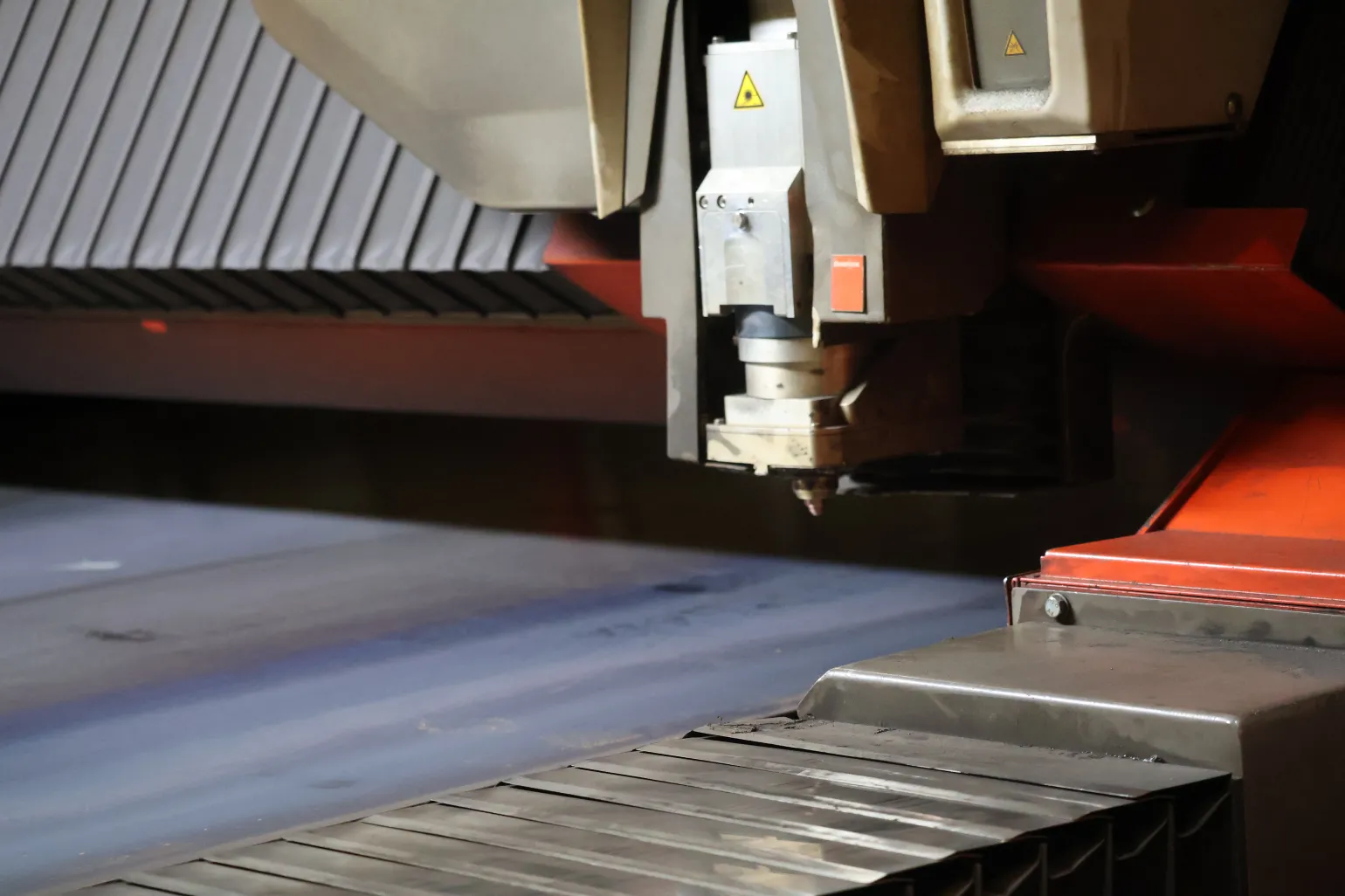

Combining flexibility, precision, and speed, the Bystronic Bystar Fiber machine is at the centre of our laser profiling services. This machine uses Fiber laser technology to emit a concentrated beam of light that can cut through metals quickly and accurately. The Bystronic Bystar Fiber is particularly effective for producing complex components with intricate details, even when producing high volumes of laser profiles.

Bystronic Bystar Fiber laser profiler machines are renowned for their high levels of precision and efficiency. They offer a range of advantages that make them ideal for laser profiles, including:

Exceptional speed: Fiber lasers are significantly faster than CO2 lasers, enabling the quicker completion of projects.

Energy efficiency: These machines consume less power compared to traditional laser cutters, reducing operational costs as well as environmental impact.

Superior cut quality: The precision of fiber lasers offers smoother edges with little to no distortion.

Low maintenance: Our laser profiling machines have fewer moving parts and require less maintenance than other machines, ensuring greater reliability and less downtime

The Bystronic Bystar Fiber machine we use to produce laser profiles is equipped with a range of advanced features, such as:

High power output: The machine can cut thick stainless steel, mild steel, and other materials with ease.

Dynamic Edge technology: Our machine’s Dynamic Edge technology ensures clean, precise cuts with minimal burrs.

Smart control interface: This laser profile machine’s smart control interface enables precise parameter adjustments for optimal cutting performance.

Automated loading and unloading: Reduced manual handling time results in enhanced efficiency.

Flexible material handling: Our Bystronic Bystar Fiber machine supports a wide range of sheet sizes and thicknesses.

Known for our commitment to quality, precision, and customer satisfaction, Pulman Steel is a reliable partner for laser profiling services. Some of the reasons why we’re the go-to choice for businesses across the UK seeking premium-quality laser profiles include:

Advanced technology: Our Bystronic Bystar Fiber machine represents the latest in laser profiling technology.

Expertise: With many years of experience in the steel industry, our highly skilled team ensures that every project meets the most stringent standards.

Sustainability: Our energy-efficient processes are one of the ways we realise our commitment to reducing environmental impact.

Custom solutions: We tailor our profiling and other services to your specific needs, offering flexibility in design, quantity, and turnaround time.

Competitive pricing: You can take advantage of high-quality services at affordable rates.

From initial consultation to final delivery, we will work closely with you to ensure that every laser profiling order is completed to perfection. Choose Pulman Steel for exceptional service and precision-engineered components. Contact us for more information about our laser profiles, expert advice, or to request a quote to take your project to the next level.